3D Knitted Material (Swing Net®)

Functional cushioning materials

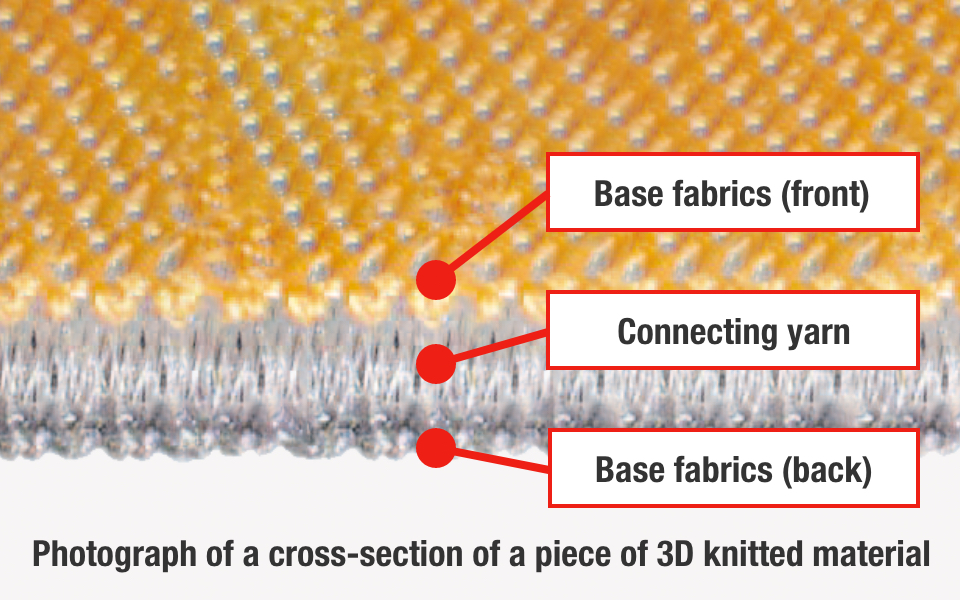

This is 3D knitted material produced using a double raschel machine. Knitted in a three-layered structure with mono-filament yarns connecting base fabrics (knitted fabrics) on the front and back, this material features a 3D structure. Changing the thickness, number, and angle of mono-filament yarns, changing the mesh weave structure of the front and back fabrics, and changing the kind of yarn all enable this knitted material to display various functional properties suitable for different applications. Applications of the 3D knitted material are expanding mainly in the field of cushioning materials.

Specifications

| Thickness | Can be set between 1.5 and 13 mm. |

| Material | PET fibers and any other fiber materials can be used. |

| Width | Can be set between 100 and 200 cm. |

| Color | Products can be manufactured in specified colors. |

| Pattern | Products can be finished in patterns in mesh or honeycomb weave; simple patterns can also be created using ultrasonic processing or the like. |

| Other features | Products can be cut and sewed in arbitrary sizes; deodorizing processing is available; folding is available. |

Features

-

- Cushioning characteristic

- Using a thick filament yarn as a connecting yarn helps maintain a 3D structure, with the spring effect of the yarn providing an excellent cushioning characteristic.

-

- Air permeability

- Changing the size of the mesh in the base fabrics allows adequate air permeability to be maintained; this alleviates stuffiness and provides coziness when sitting.

-

- Body pressure dispersing characteristic

- Compared with ordinary cushioning materials, these textiles are characterized by the feature of dispersing pressure in areas where pressure concentrates, substantially reducing the feeling of tiredness during long-time use.

-

- Expansion-contraction stability

- The knitted weave structure produced by a double raschel machine results in excellent expansion-contraction stability.

-

- Durability/Price

- As a cushion-structured body, this product excels in repeated compression and tensile characteristics; it also excels in chemical resistance, launderability, and weatherability, helping suppress operating costs.

For inquiries, please contact:

Functional Materials Business Division, Functional Materials Business Headquarters, SUMINOE Co., Ltd.