The Story of SUMINOE Carpet Woven with Anecdotes about the Times, People and Lifestyles

135 years have passed from SUMINOE's founding and 105 years have passed from its incorporation as a company. Throughout its history, SUMINOE has woven together forward-looking entrepreneurship as its warp, and solutions to enrich people's lives as its weft, while continuing to offer people amenity spaces and enriched lifestyles, thereby enlivening various aspects of our country, society and lifestyles. Our Company has taken on diverse challenges and innovations, positively overcoming a variety of difficulties. Our history can be likened to a unique carpet embodying the essence of the times and the dedication of our people. We hereby present SUMINOE's corporate history, the unique story of a company truly committed to the well-being society.

ⅠFounding—Contribution to Japan’s Modernization

The history of SUMINOE began when a rice dealer who foresaw a prosperous future for carpets encountered a kimono merchant who wished to engage in commerce with the world.

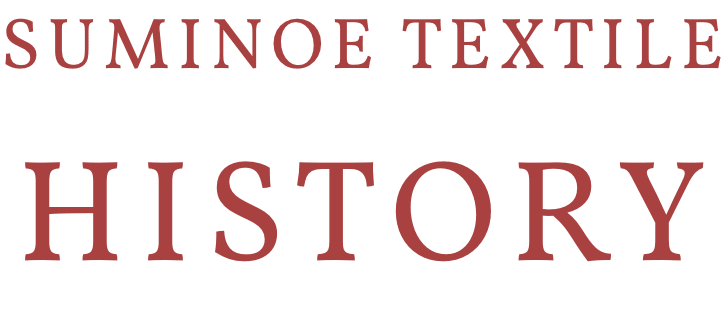

SUMINOE was founded by rice dealer Denshichi Murata, who opened the Murata Factory in 1883 in Sumiyoshi Village, Higashinari-gun, Osaka Prefecture (now Sumiyoshi Ward, Osaka City).

Originally started as a side business in a private household, this small factory for manufacturing hand-woven carpets was soon receiving orders for interiors for railway cars and ships, and even for the Imperial Diet Building, heralding the dawn of Japan’s carpet industry. This was the outcome of the close ties with Takashimaya that Denshichi Murata had built up since their first encounter. Takashimaya (now one of Japan’s leading department store retailers) was a long-established kimono merchant, which had then moved to expand its overseas trading activities in response to international demand, and which was also aggressive in supplying textiles for interiors.

Our founder, Denshichi Murata, who was honest, persistent and extremely studious

Our founder, Denshichi Murata, who was honest, persistent and extremely studious

Denshichi Murata was born in 1848 as the seventh son of Denbei Murata, in the Town of Sawa, Higashinari-gun, Osaka Prefecture. Denshichi grew up to be a rice dealer who ran a store named “Komeden.” At that time, hand-woven carpets called “Sakai Dantsu” were widely manufactured, as a side business, in the area from Sakai to Osaka Sumiyoshi, as export items to the United States.

Motivated by this situation, Denshichi Murata purchased three looms and began to manufacture carpets while running a rice store. He started manufacturing carpets at the Murata Factory, which became the origin of Suminoe Textile. Our founder, Denshichi Murata, was a trustworthy, warmhearted and hard-working person who persistently stuck to manufacturing of high quality products. The Murata Factory made remarkable progress in its carpet-weaving techniques, and he eventually closed his rice business so as to concentrate solely on manufacturing carpets.

What is dantsu?

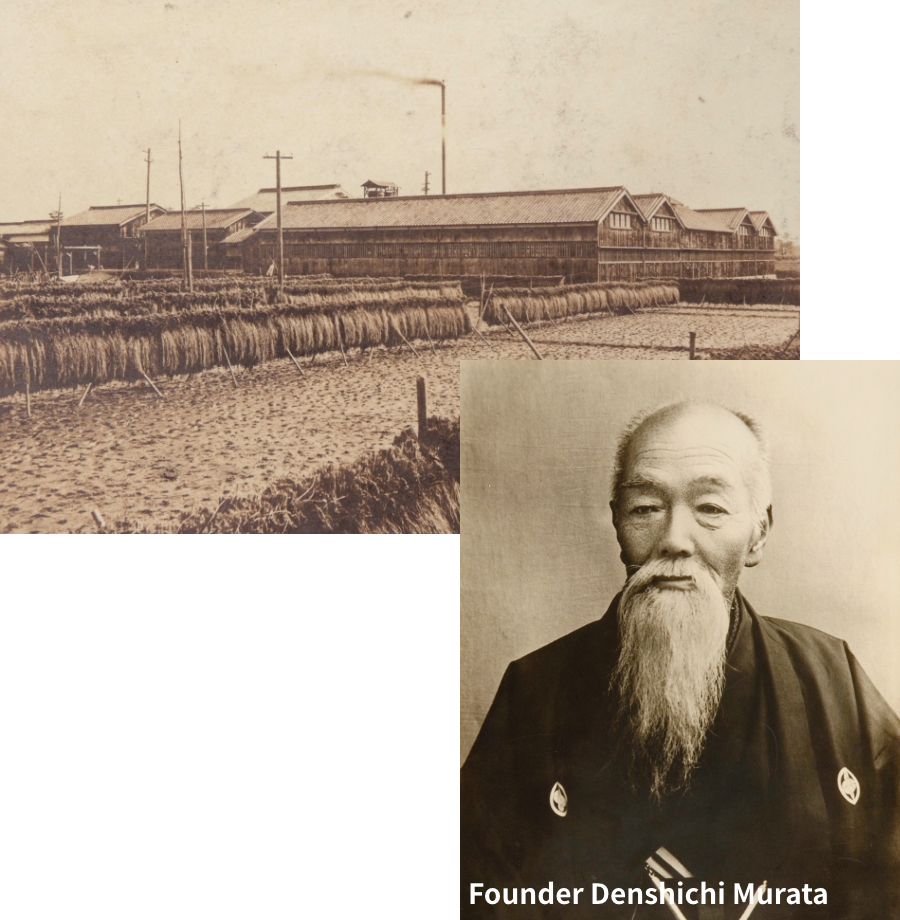

Dantsu is a generic name for traditional hand-woven floor carpets or rugs made by knotting pile yarns to warp threads. Pile yarns are knotted by hand to the warp threads of a base fabric, and the resulting product is then cut to make tufts. The method used to knot pile yarns varies according to the districts that produce dantsu, which can be classified into Chinese Dantsu, Persian Dantsu, Turkish Dantsu, etc. Weaving a dantsu carpet requires a great deal of technical skill, and it takes many days for its completion. Dantsu are therefore expensive and luxury carpets that are often treated as artistic handicrafts.

Contributing to the establishment of Japan’s image as a modern state by supplying carpets to renowned buildings in the Meiji Period

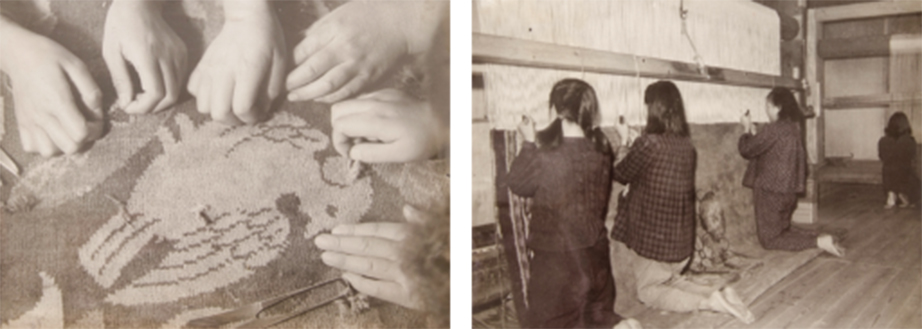

Imperial Diet Building

Imperial Diet Building

Takashimaya, which paid special attention to the high-level techniques of the Murata Factory, placed an order with Denshichi Murata for the manufacture of carpets to be delivered to the Imperial Diet Building. These carpets had been initially ordered by the Meiji government. In 1891, the Murata Factory accomplished this great task of supplying the carpets to the then Diet Building in Hibiya, Tokyo on the occasion of its opening. The Murata Factory also received an order for interior textiles for the present-day Diet Building, completed in 1936, and delivered the “red carpet” and seat coverings used in the chambers of both the House of Councillors and the House of Representatives.

Suminoe Textile’s first “intellectual property”

Suminoe Textile’s first “intellectual property”

In 1890, Denshichi Murata, who was a highly studious craftsman, manufactured the first Wilton-style carpet made in Japan. In 1892, he received a patent for the carpet weaving, which was named “Yamato-ori.”

What are Wilton carpets?

Machine-woven Wilton carpets are named after the town of Wilton in England where they were first manufactured in the mid-18th century. In the 19th century, Wilton carpets with a variety of designs became able to be produced by weaving pile yarns in two to five colors by using Jacquard cards. Wilton carpets feature great durability and convey a sense of luxury.

The comfortable feel of moquette seat covering and its distinctive design enhanced the joy of riding on public transportation

Japan National Railways

Japan National Railways

In March 1870, the Japanese government launched its first railway project. The first trains featured three classes: upper, intermediate and lower. The upper and intermediate passenger cars used imported moquette as fabric for the seat covers. The Japanese government subsequently asked Takashimaya to supply Japan-made moquette for the seats, and our Company received an order from Takashimaya to manufacture the seat covers. In 1896, we succeeded in producing hand-woven moquette as a seat covering for the first time in Japan. This domestic moquette was adopted by Japan National Railways for their seat coverings in 1899.

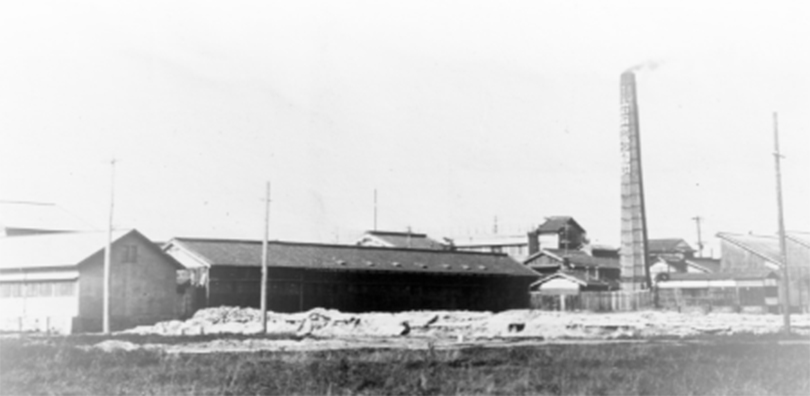

Construction of Sumiyoshi Factory

Construction of Sumiyoshi Factory

After successfully accomplishing a series of major projects contributing to the establishment of social infrastructure, Denshichi Murata purchased land in what later became Sumiyoshi Ward, Osaka City in 1903, to pave the way for further development. On this land he constructed the Sumiyoshi Factory, which functioned as the main factory of Suminoe Textile for many years, while also serving as a cradle of Japan’s interiors industry. The Sumiyoshi Factory then gradually developed through building extensions and other additions, with its brick chimney enjoying popularity as a symbol of the factory.

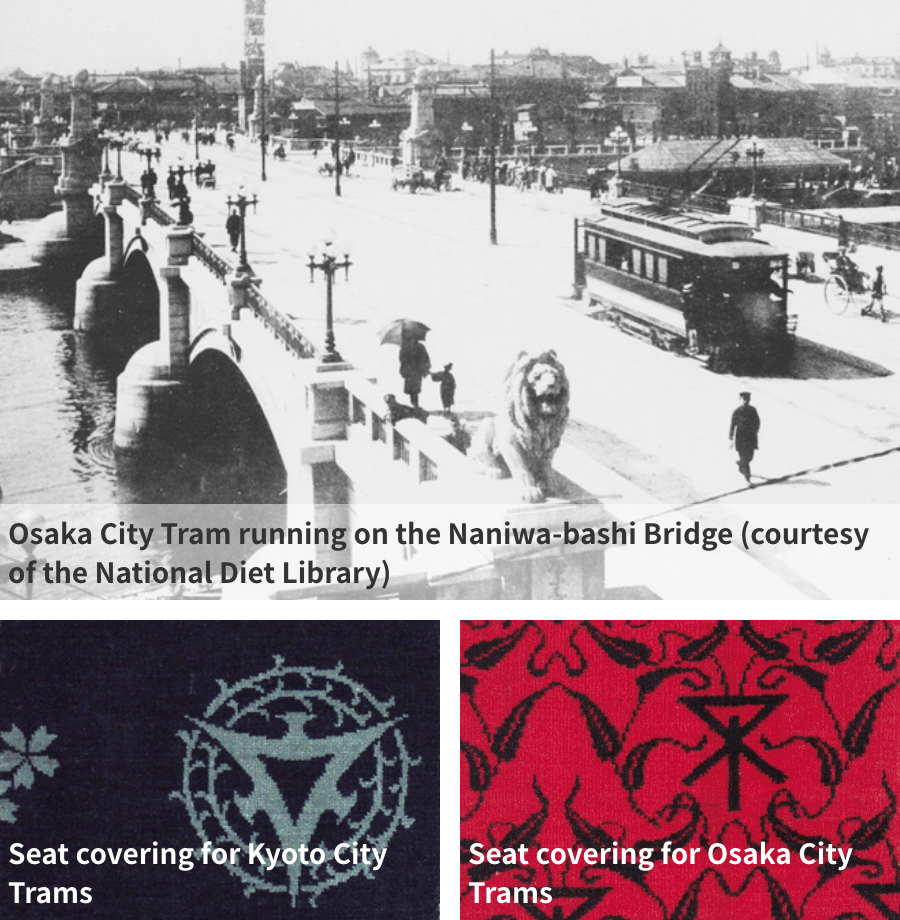

Trams

Trams

Trams, which began to run in Kyoto in 1895, became widely introduced in various parts of Japan as a means of transportation for the general public. Our Company designed moquette seat covering featuring city emblems for a number of these tram systems. Later it became a popular trend to incorporate city emblems in seat cover designs for city trams nationwide. As a motif for the seats of Osaka City trams, we used Osaka City’s emblem, the miotsukushi (a marker to warn ships away from shallows and sandbanks).

What is moquette?

Moquette is a hand-woven fabric originating in France. Featuring a dense surface formed by short, upright piles, moquette offers a smooth feel and excels in durability. Even today, moquette fabrics are widely used for the seat coverings for buses and railway cars.

Meiji Period (Brief Chronology of the Company’s History)

- 1883

- Founder Denshichi Murata begins manufacturing handwoven carpets in Sumiyoshi, Osaka.

- 1891

- Carpets supplied to the Imperial Diet Building (now the Diet Building).

- 1899

- Seat coverings manufactured for the first time in Japan adopted by Japan National Railways.

- 1903

- Sumiyoshi Factory with full-scale weaving facilities established.

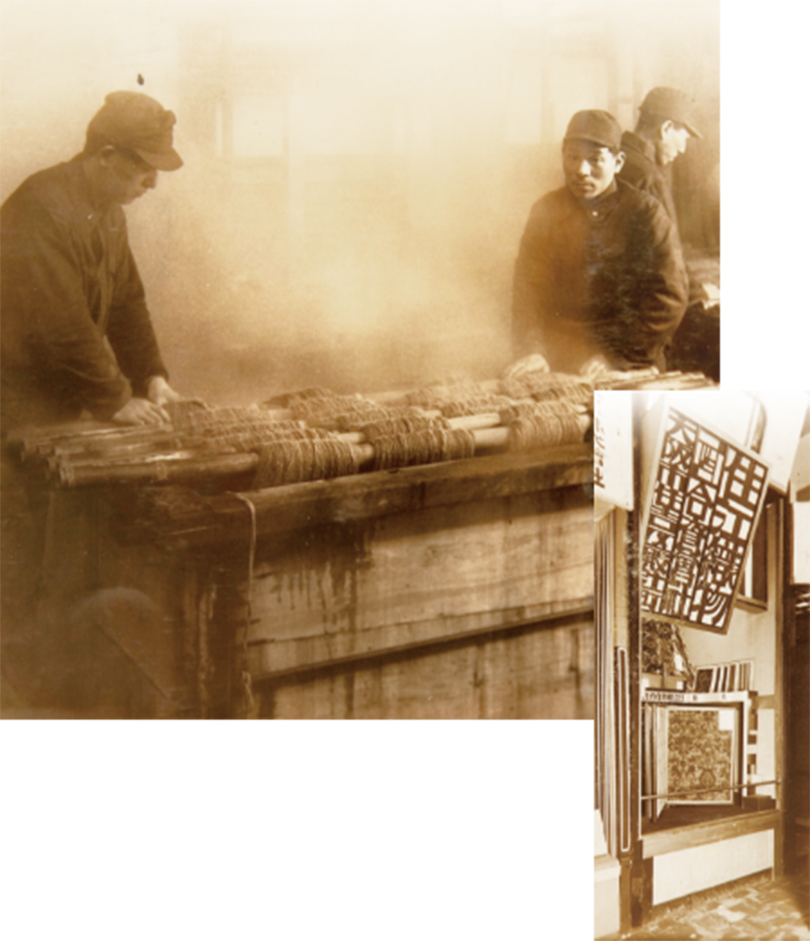

Advancing into the realm of culture and art embellishing the modernism of the Taisho Period

In accordance with the improvement in living standards and a change to Western-style lifestyles, interior textiles became a trend of the Taisho period. With increasing offers from Japan National Railways, its greatest customer, the Murata Factory was thriving, generating impetus for a shift from hand looms to modern power looms.

Establishment of Suminoe Textile Joint-Stock Company

Establishment of Suminoe Textile Joint-Stock Company

In response to the needs of the new era, momentum accelerated for conversion from a private operation to incorporation as a company. This led to the establishment of Suminoe Textile Joint-Stock Company in 1913, which was jointly invested by the Murata family and the Iida family of Takashimaya. The Company’s establishment marked the first step in the 100-year history of Suminoe Textile as a corporate body. Denshichi Murata was appointed as the first President, and Isao Mashiko, who later became the second President, was elected as Manager.

Origin of the Company name “Suminoe Textile”

It is said that Suminoe Textile Joint-Stock Company was so named because of its association with the Suminoe shore, which was located in close vicinity to its factory. The Suminoe shore is a scenic spot and place of historic interest, also appearing in a famous tanka poem composed by Fujiwara no Toshiyuki Ason (?-901). The tanka poem reads:Suminoe no Kishi ni yoru nami

Yoru sae ya, Yume no kayoiji

Hitome yoku ran.(The Suminoe shore is approached by wave after wave. Even at night, on the pathways of dreams, why do I fail to see you?)

The name evokes a romantic atmosphere, and is eminently suitable for an interiors company.

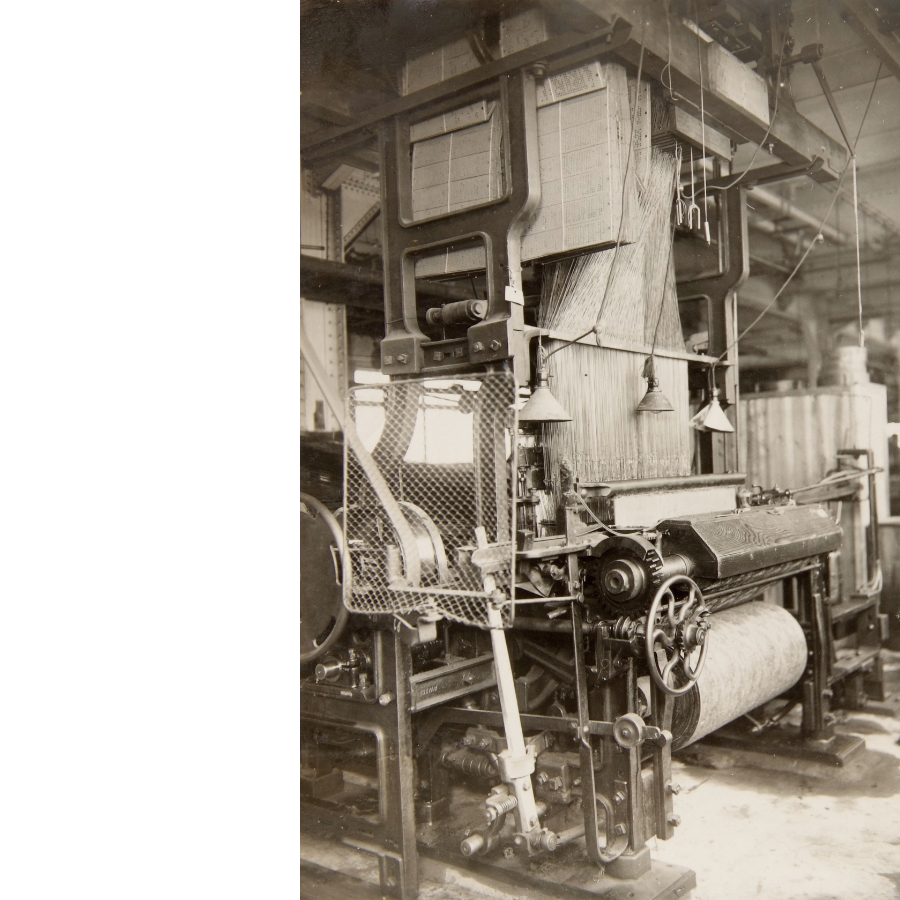

Introducing technology and power looms from Germany and the U.K.

Introducing technology and power looms from Germany and the U.K.

In 1913, Suminoe Textile Joint-Stock Company imported technology and power looms from Germany and the U.K., becoming the first company in Japan to manufacture machine-woven moquette. The resulting products were used as seating material for the first class cars of Japan National Railways, and in cars of private railways. In 1916, the Company started to manufacture carpets using power looms.

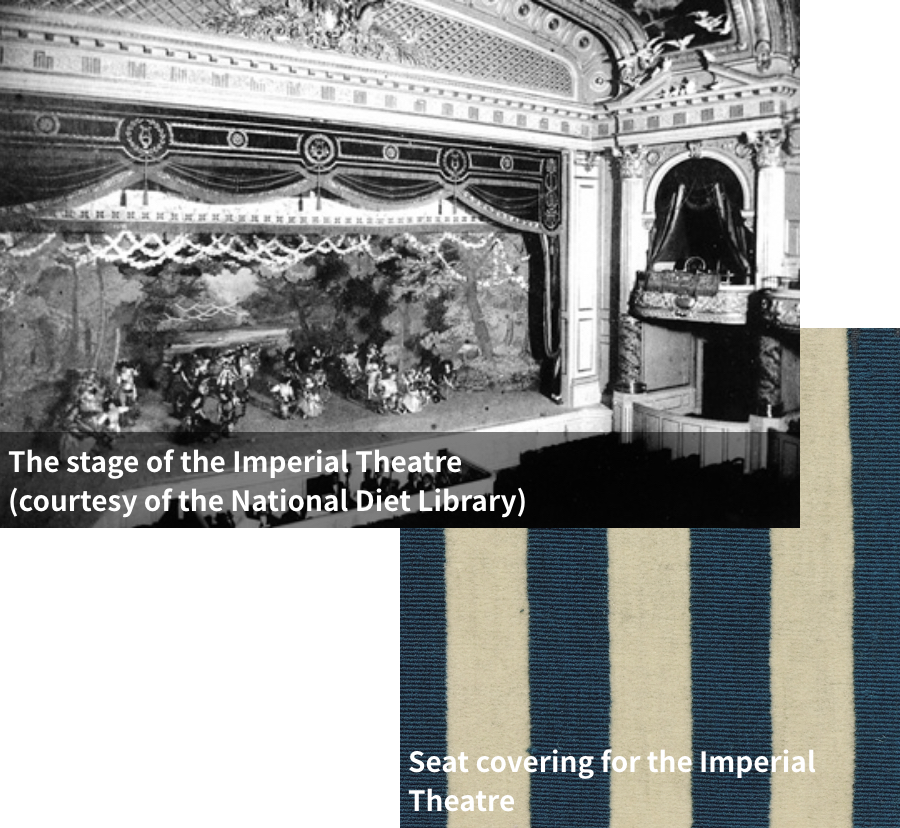

Imperial Theatre

Imperial Theatre

In 1915, the Company delivered seat coverings to the Imperial Theatre. Suminoe Textile’s seat coverings were also adopted when the Imperial Theatre underwent extensive renovation in 1966. In this prestigious entertainment theatre, which is known to many Japanese people by its nickname “Teigeki,” our highly comfortable seat coverings have helped audiences enjoy stage performances over many years.

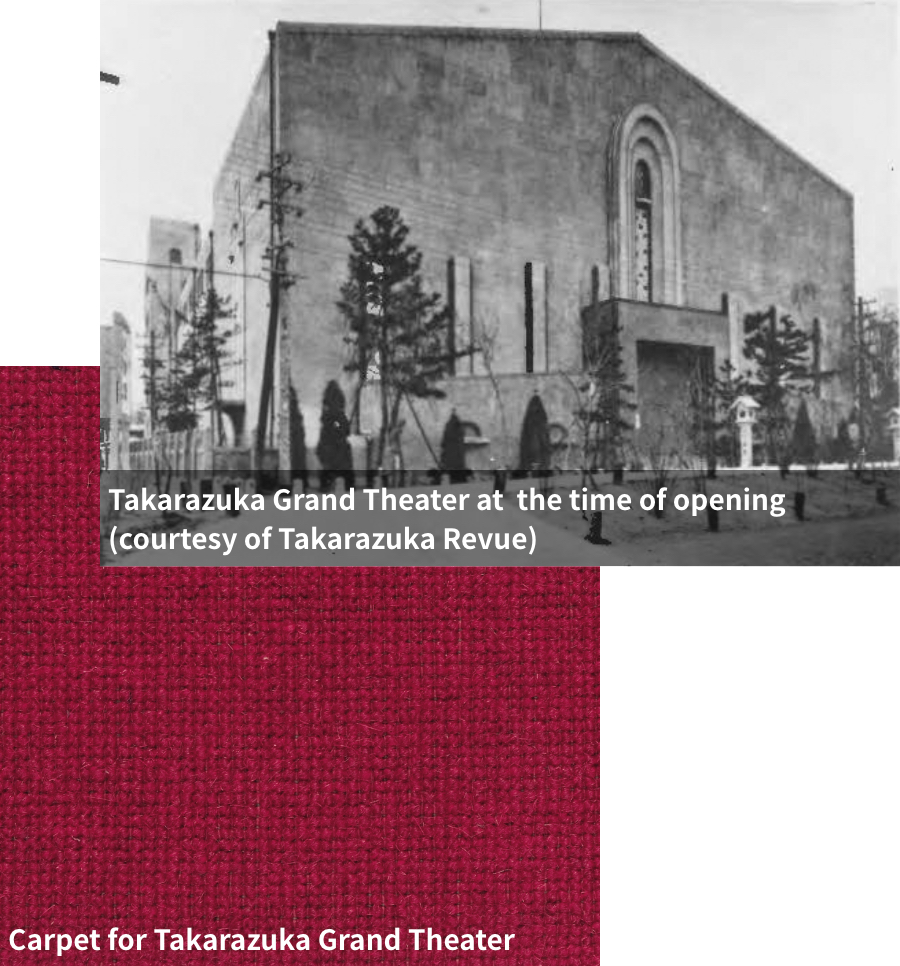

Takarazuka Grand Theater

Takarazuka Grand Theater

Takarazuka Grand Theater, opened in 1924 in Sakae-machi, Takarazuka City, Hyogo Prefecture, has a seating capacity of more than 3,500. Suminoe Textile has continued to supply seat coverings and carpets to this theater since its opening to the present day. The seats on which Takarazuka fans have sat to view the performances of their adored Takarajennu (Takarazuka actresses) preserve the memories of Suminoe Textile, which has watched over and supported the glorious history of Takarazuka stage stars.

Taisho Period (Brief Chronology of the Company’s History)

- 1913

- Suminoe Textile Joint-Stock Company established.

By introducing technologies and power looms from Germany and the U.K., manufacture of machine-woven moquette begins for the first time in Japan.

- 1916

- Manufacture of carpets using power looms begins.

Mohair plush produced and adopted for seating material for the first-class cars of Japan National Railways, and in cars of private railways.

- 1925

- Manufactures flags for His Imperial Highness the Crown Prince of Japan.

Achieving regeneration overcoming the calamity of war, by becoming involved in the automotive industry in its Infancy

At the beginning of the Showa Period (1926-1989), information and transportation networks began to connect people around the world. Toward the age of mass production and mass consumption to come, Suminoe Textile achieved regeneration and development overcoming the calamity of war, inspired by the dynamism of the times.

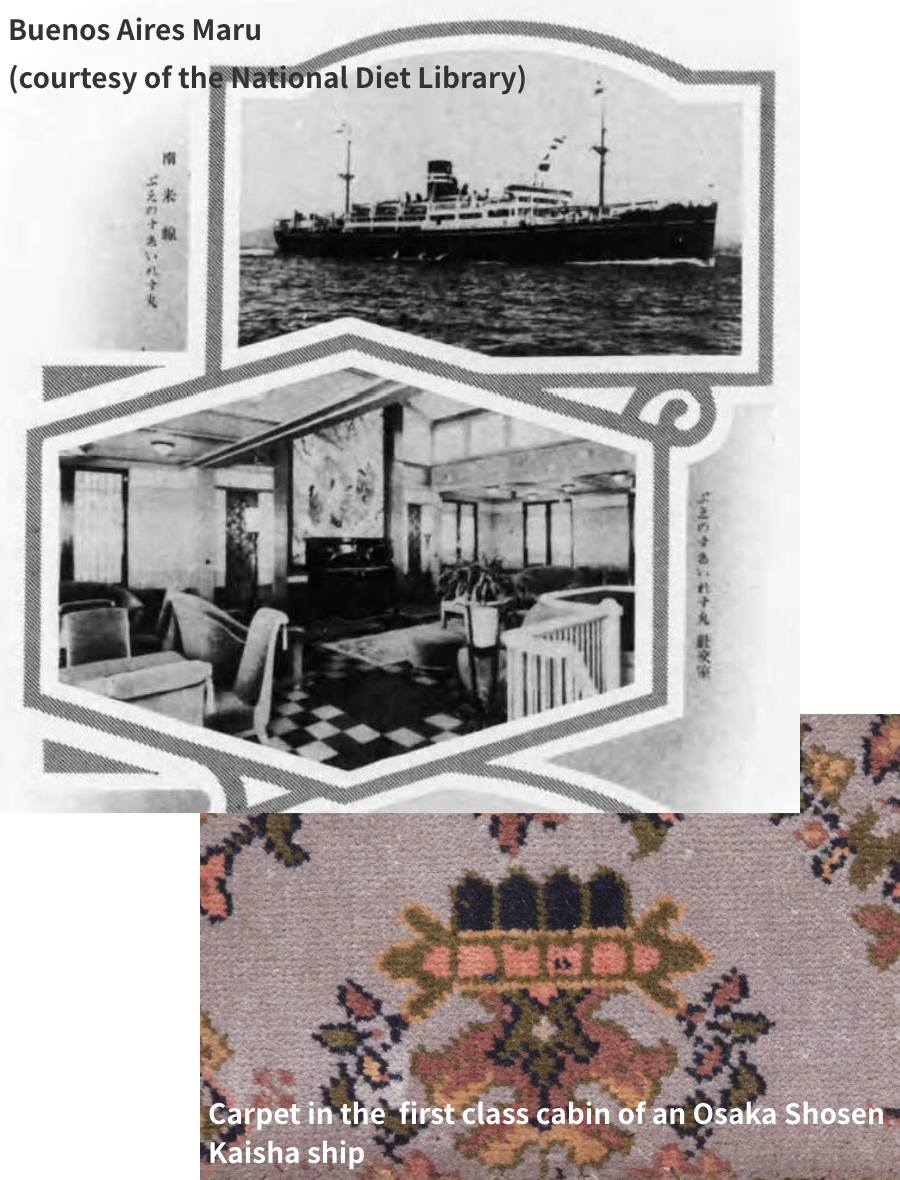

Vessels

Vessels

In the 1920s, passenger ships were used for all overseas travel. Luxury liners, represented by the Titanic, which was featured in a famous movie, navigated the oceans of the world. Suminoe Textile supplied carpets to the first class cabins of liners operated by Osaka Shosen Kaisha (now Mitsui O.S.K. Lines, Ltd.). In the Showa Period, our Company’s products were adopted by almost all of Japan’s renowned vessels, including the Brasil Maru, the Argentina Maru, and the Buenos Aires Maru, which were used by many people to go to Latin America for emigration and tourism. At that time, interior materials for ships were at the forefront of fashion, exercising influence over interior design in general.

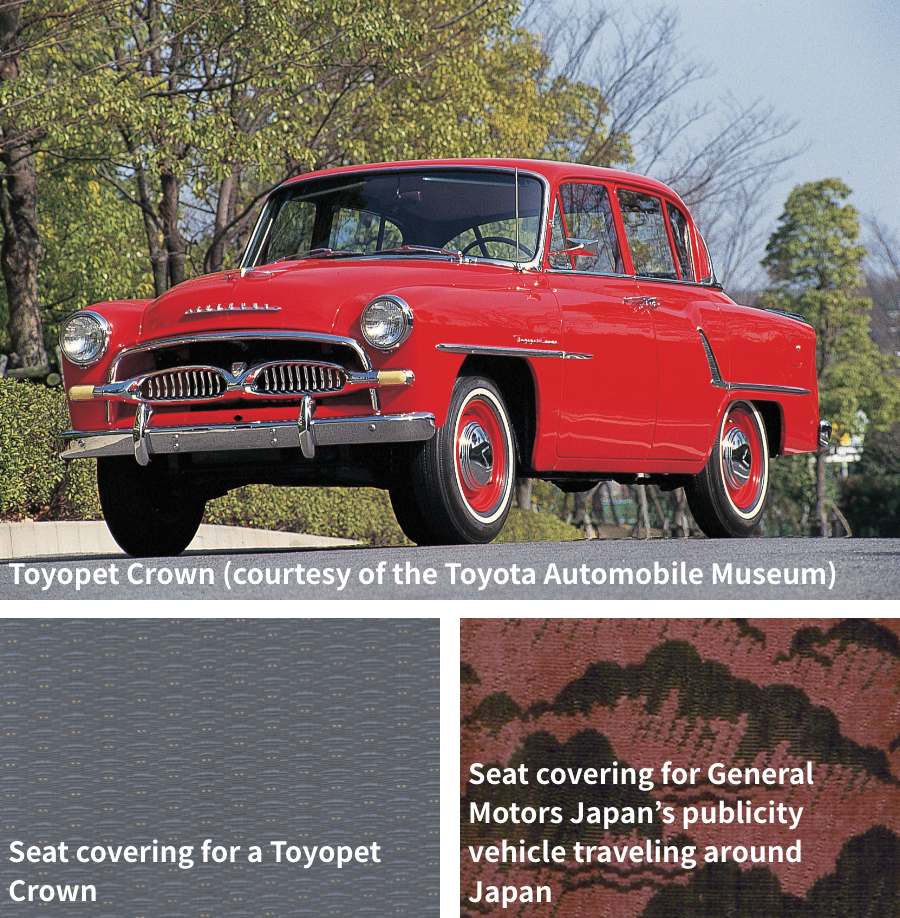

Automotive industry

Automotive industry

In 1931, Suminoe Textile supplied carpets and seat covering materials to automobiles assembled and manufactured in Japan for Ford Motor Company and General Motors from the United States. In so doing, Suminoe Textile participated in the automotive industry in its infancy. Based on this traditional advantage, our Company delivered nylon seat coverings to Toyota Motor Co., Ltd. (now Toyota Motor Corporation) in 1958. Since then, our products have been used by various Japanese automobile manufacturers one after another. Even today, the connection we have established with the automotive industry is one of the main pillars of our Company’s business operations.

Special procurement demand from the Occupation Forces

Special procurement demand from the Occupation Forces

In the wake of the defeat in World War II, Japan’s carpet industry was in a state of suspended animation, with looms and weaving machines gathering dust. The regeneration of the industry was triggered in February 1946 by the great number of orders that Suminoe Textile received from the Occupation Forces, to procure textile products for American soldiers’ barracks, billets, and their family housing. An unprecedentedly high demand for carpets and moquette was generated, forcing us to work day and night to manufacture these products at full capacity. Since the orders were too large to be fulfilled by our Company alone, we called for help from the nation’s entire carpet industry, which worked together with us to complete these orders. Although there were some bitter incidents, including confrontations with U.S. officers about delivery times, this “special procurement demand” brought hope for the postwar reconstruction of Japan’s carpet industry.

Beginning of Showa Period (1926) – Showa Period 20s (Brief Chronology of the Company’s History)

- 1930

- Suminoe Textile Co., Ltd. established.

- 1937

- Kawachi Factory established, where woolen spinning begins.

- 1943

- Kyoto Factory established, where drape production begins.

- 1947

- Amino Factory (now TANGO TEXTILE Co., Ltd.) established, as a manufacturing site of plush hand-woven curtains, hand-woven carpets and hooked rugs.

- 1949

- Shares listed on the Tokyo, Osaka, and Kyoto stock exchanges.

ⅡPopularizing Interior Fabrics in Common Households

Carpets becoming necessities for daily living against the backdrop of a remarkable economic recovery

Rising from the ashes of war, Japan stunned the world by making an economic recovery at tremendous speed, driven by the Japanese people’s “hungry spirit” and diligence, as well as bold industrial innovations. In the Showa 30s (1955-1964), Japan entered a period of high economic growth. Later, following the success of a series of major national events, including the Tokyo Olympic Games and the Japan World Exposition, Japan’s national income increased as well. The phrase “the age characterized by the all-Japanese-are-middle-class mentality” became widely used. With further westernization of Japanese people’s lifestyles, carpets shifted from being high-end goods to necessities for daily living, which also significantly changed the corporate activities of SUMINOE.

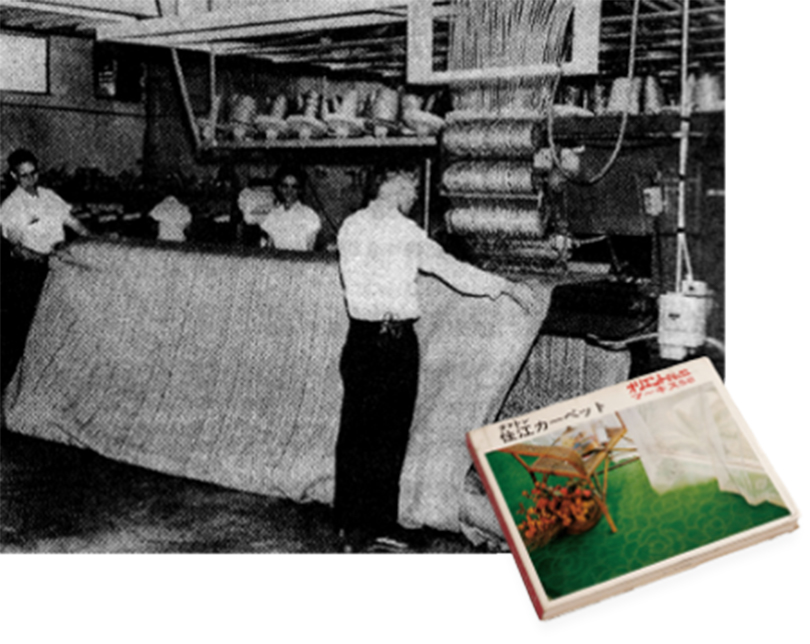

Introduction of a tufting carpet machine

Introduction of a tufting carpet machine

In 1954, the Company imported from the United States a tufting carpet machine capable of mass production for the first time in Japan. The carpets mass-produced by such machines are collectively called “tufted carpets.”

What are tufted carpets?

Tufted carpets are made by a method that was invented in the United States and that has enabled mass production. This type of carpet developed dramatically in the 1950s and onward. Tufted carpets are made on specialized multi-needle sewing machines, where several hundred needles stitch hundreds of rows of pile yarn tufts through a pre-constructed backing fabric. The production speed of tufted carpets is approximately 30 times that of Wilton carpets. Previously, solid color tufted carpets were predominant. In recent years, however, with the introduction of computers, the majority of tufted carpets produced have come with a variety of colors and patterns.

Imperial visit to the Sumiyoshi Factory

Imperial visit to the Sumiyoshi Factory

In the autumn of 1956, Their Imperial Majesties the Emperor and Empress Showa visited our Sumiyoshi Factory after attending the 11th National Sports Festival held in Hyogo Prefecture. The 3rd President, Kizo Iida, had the privilege of guiding Their Majesties around the weaving mill, product display room, finishing shop and tufting factory.

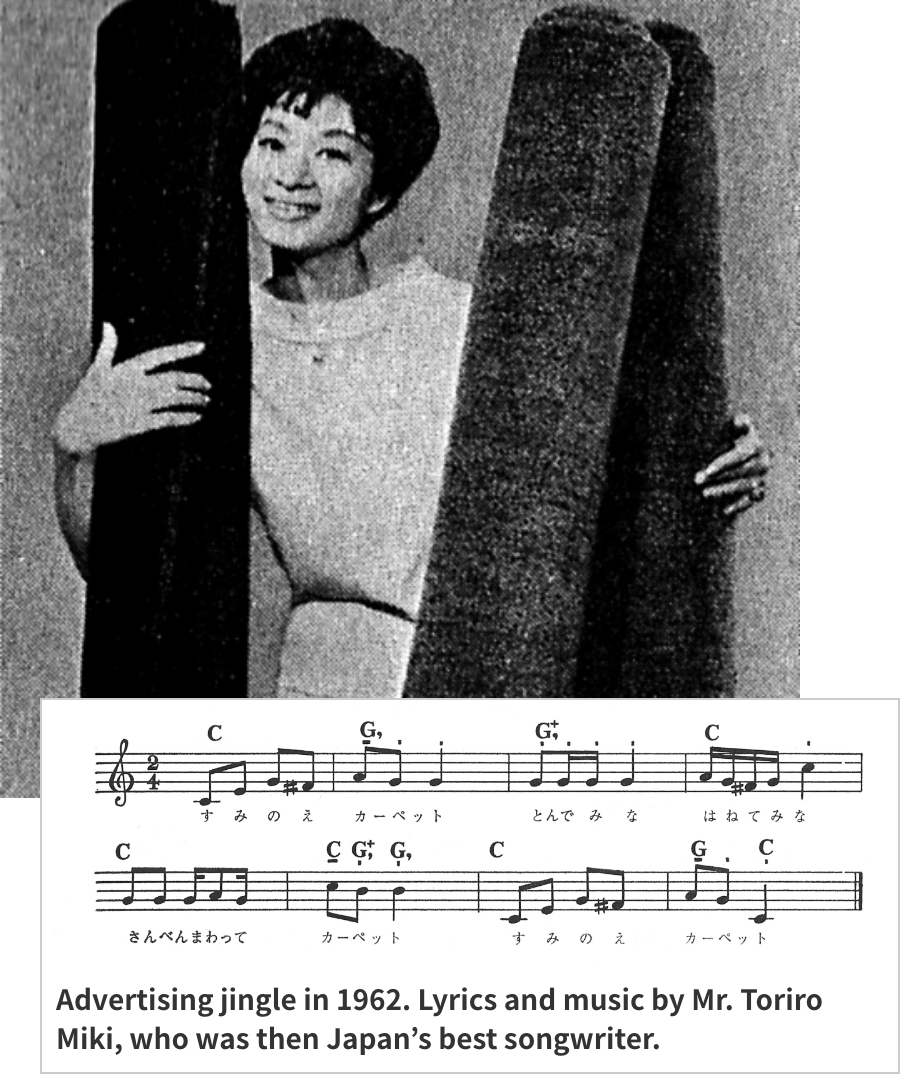

“Tafton” carpets released on the market

“Tafton” carpets released on the market

In 1957, a new carpet called “Tafton” is released. Under the concept “a carpet that can be purchased by an average section-chief-level company worker using a bonus,” the retail price for a four-and-a-half tatami mat-sized carpet was set at 9,900 yen at that time. This marked a turning point in carpet production, from conventional custom-made manufacturing to ready-made production.

When the Company released “Tafton,” its advertisements enjoyed widespread popularity. Tafton became a topic of conversation among Japanese as an innovative product that could transform their lifestyles. As a result, carpets, which had been high-end products until then, came to be widely used by ordinary households all of a sudden.

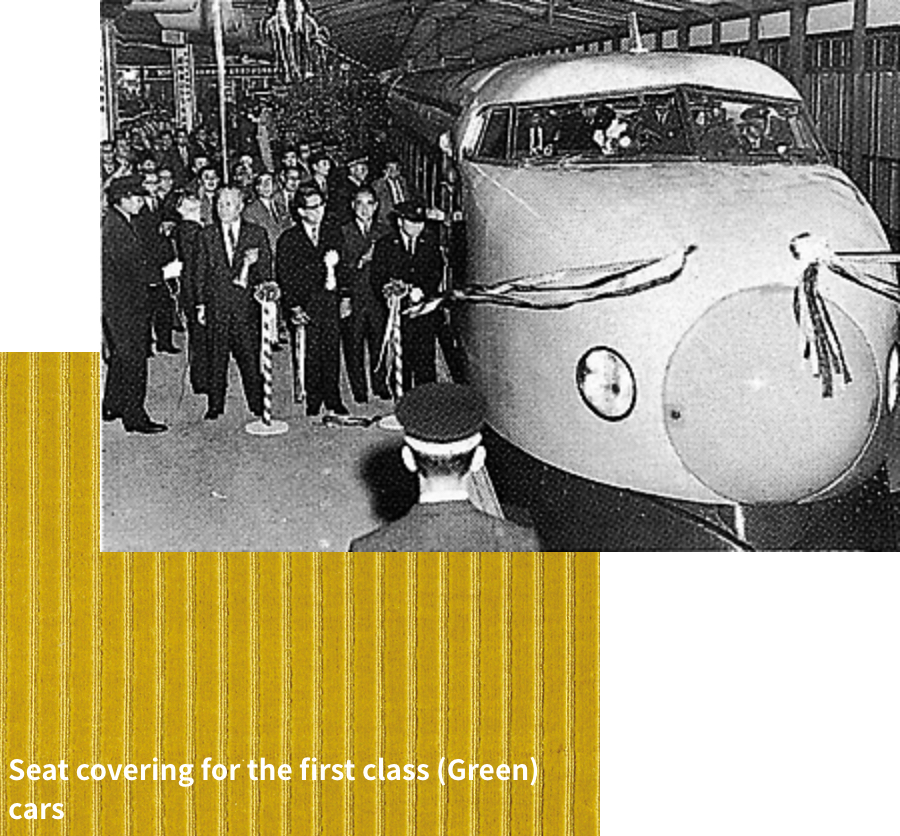

The Shinkansen bullet train

The Shinkansen bullet train

In recognition of our achievement of having supplied seat coverings for Japan’s first railway cars, our products were adopted by Japan National Railways. Suminoe Textile has continued to supply seat covering materials to Japan National Railways (now Japan Railways) and private railways, and we are extremely proud of the top market share we have held in this field for more than one century. In 1964, when the Tokaido Shikansen of Japan National Railways went into operation, our Company supplied seat coverings for the first class (Green) cars and the standard cars of the 0 series trains, which were then promoted as “the Dream Superexpress”.

Did Suminoe Textile really manufacture an automobile!?

It is a little known fact that Suminoe Textile manufactured and sold a two-seater convertible in 1955, in anticipation of the age of motorization to come. The car, called the “Flying Feather,” was a small car that pursued compactness and lightness, with the aim of “achieving maximum performance with minimum possible fuel consumption.” The Flying Feather was manufactured by Suminoe Manufacturing Co., Ltd., a Suminoe Textile subsidiary, which was engaged in producing car bodies for Nissan automobiles, such as Datsan sedans. Although the Flying Feather was not mass-produced, this memorable anecdote symbolizes the entrepreneurship of Suminoe Textile, which has pursued new challenges without being afraid of taking risks.

Supplying a hand-woven carpet to an Imperial Palace building newly constructed in the Showa Period

Supplying a hand-woven carpet to an Imperial Palace building newly constructed in the Showa Period

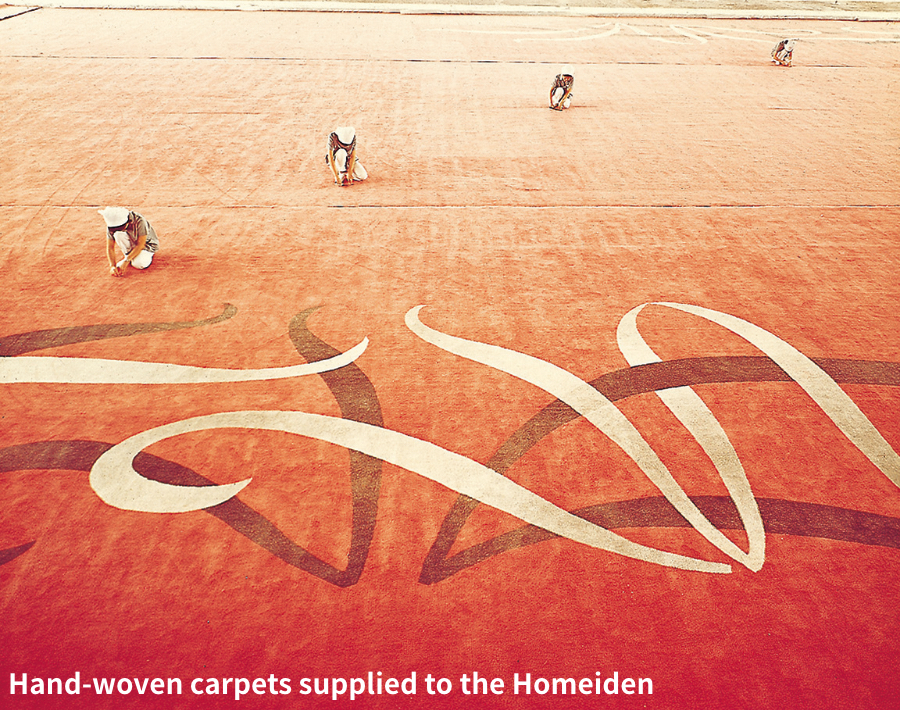

The Homeiden, newly created in the Showa Period, is one of the Imperial Palace buildings, and is used to hold major banquets. This banquet hall is the largest of all the palace halls. The Homeiden building consists of only one room, making it the most spacious room in the Imperial Palace. In 1968, Suminoe Textile provided for this hall a gorgeous and dignified hand-woven carpet with a design based on a painting by Yasushi Sugiyama, a distinguished Japanese-style painter. Featuring grass patterns designed by him, this Chinese-style dantsu carpet is laid on the hall’s floor, covering an area of about 540 tatami mats (22×38m/836㎡). To manufacture a carpet that could cover such a large floor space, we had to join together three carpets about 7m wide and 37m long. The manufacturing process was very extensive, requiring a total of 10,000 weavers, who spent as long as nine months knotting 65 million tufts by hand, to complete this masterpiece carpet.

Construction of the Nara Factory

Construction of the Nara Factory

In the Showa 40s (1965-1974), the Japanese economy shifted from the high growth period to enter a period of stable growth. In that period, along with the information and leisure industries, the housing industry began to step into the limelight, boosting demand for carpets and curtains and thus causing production of these products to accelerate. To meet the demands of the new age, we had to seek a larger block of land on which to establish a modern facility to replace the Sumiyoshi Factory─which had, until then, consistently functioned as our main factory. Our Company was also forced to take drastic measures for environmental protection and pollution control, which had become grave matters of social concern by that time. For these reasons, Suminoe Textile purchased a tract of land of 30,000 tsubo (approximately 100,000㎡) in an area about 3 km southeast of the Horyuji Temple. In 1970, we began construction of the Nara Factory, which was completed in September 1971. This was the launch of our pollution-free carpet factory, the largest of its kind in Asia at that time.

Japan’s first carpet tiles

Japan’s first carpet tiles

In 1980, the Nara Factory began production of Japan’s first carpet tiles. By laying equal-sized squares of carpet like tiles, colorful mosaic patterns can be formed. It is also easy to replace the damaged carpet tiles with new ones. With these advantages, our carpet tiles attracted much attention as an innovative product. Today, one of our key products is “ECOS®,” the world’s premier eco carpet tiles, which are made from up to 84% recycled materials and feature a carbon footprint reduction of up to 43% compared to our conventional products.

Showa Period 20s – Showa Period 60s (Brief Chronology of the Company’s History)

- 1954

- First to introduce to Japan the tufting carpet machine from the U.S.

- 1955

- The Flying Feather, a pioneering small car made in Japan, manufactured and sold by Suminoe Manufacturing Co., Ltd., a subsidiary of Suminoe Textile Co., Ltd.

- 1956

- Both Their Majesties the Emperor and Empress of Japan visit the Suminoe Factory.

- 1964

- Moquette supplied for seats in the 0 Series Shinkansen bullet trains.

- 1968

- Hand-woven carpets and Tango carpets supplied to a new Imperial Palace building (Homeiden).

- 1971

- Nara Factory (now Nara Factory of Suminoe Techno Co., Ltd.) established, and Sumiyoshi Factory closed.

- 1980

- Nara Factory begins production of Japan’s first carpet tiles.

- 1985

- Shares of Koken Industrial Co., Inc. (now RUNON CO., LTD.) acquired, which becomes a subsidiary of Suminoe Textile Co., Ltd.

- 1987

- Shiga Office established.

ⅢOffering One-of-a-Kind Products to Customers around the World

Building a unique brand from a global perspective in the post-Cold War world

In the 1990s, politics and economies began to move in a single larger framework after the collapse of the Berlin Wall, which had symbolized the Cold War between the East and West. SUMINOE began to advance into the new age, aiming to strike a balance between concern for the global environment and corporate growth.

Producing a fiber from PET bottles

Producing a fiber from PET bottles

Suminoe Textile, in line with its corporate policy of always being committed to producing unique products, has continued its efforts to realize integrated production. One example is the project to develop a fiber made from recycled PET bottles. This was launched at the end of the Showa Period and realized in the Heisei Period (1989-2019). We needed to make a heavy prior investment in facilities and human resources for this project, which took some time to become economically viable. However, our spirit of entrepreneurship, which places priority on original manufacturing, has motivated us to carry through with this project. As a result, we have successfully developed an original polyester fiber SUMITRON® made from recycled PET bottles.

Global network for our automobile textiles business

Global network for our automobile textiles business

After establishing a subsidy that produce automotive textiles in Thailand in 1994, Suminoe Textile expanded its global business network by setting up manufacturing and sales sites in the United States, China, Indonesia, India and Mexico. At present, in the automobile textiles segment, overseas sales account for roughly half of total sales. In the future, we will continue to aggressively promote expansion overseas, aiming for the creation of a globally optimized supply system.

Overseas Expansion (Brief Chronology of the Company’s History)

- 1994

- T.C.H. Suminoe. Co., Ltd. established as a joint venture in Thailand.

- 2003

- Suminoe Textile of America Corporation established in the U.S.

Suzhou Suminoe Textiles Co., Ltd. established in China.

Suzhou Suminoe Koide Automotive Accessories Co., Ltd. established as a joint venture in China.

PT. Sinar Suminoe Indonesia established as a joint venture in Indonesia.

- 2005

- SPM Automotive Textile Co., Ltd. established as a joint venture in China.

- 2010

- Suminoe Textile Shanghai Co., Ltd. established in China.

Suminoe Teijin Techno Krishna India Pvt. Ltd. established as a joint venture in India.

- 2013

- Suminoe Textile de Mexico, S.A. de C.V. established in Mexico.

PT. Suminoe Surya Techno established as a joint venture in Indonesia.

- 2015

- Acquires Bondtex, Inc. in the U.S. and makes it a consolidated subsidiary.

- 2018

- Suminoe Koide (Thailand) Co., Ltd. starts up operations in Thailand.

- 2019

- Suminoe Textile Vietnam Co., Ltd. established in Vietnam.

Around-the-clock deodorizing treatment technology TRIPLE FRESH®

Around-the-clock deodorizing treatment technology TRIPLE FRESH®

In 1998, Suminoe Textile developed TRIPLE FRESH® treatment technology, which can chemically and physically absorb and decompose formaldehyde (which is said to be one of the causes of sick house syndrome), cigarette odor, garbage odors, the smell of sweat and other malodorous substances that are generated daily in our environment, on a 24-hour basis. Currently, TRIPLE FRESH® treatment technology is finding wide application not only for interior products such as carpets, curtains and wallpaper, but also for seat coverings of automobiles and train cars, as well as deodorization filters used in refrigerators and air purifiers.

Our Development Concept: “Resources for the future.”

![[ECOS®︎] Double Recycle System](https://suminoe.co.jp/cms/wp-content/themes/suminoe-textile/assets/img/en/company/history/img_ecos.png)

Development of ECOS®, eco-friendly carpet tiles under the horizontal recycling system

Development of ECOS®, eco-friendly carpet tiles under the horizontal recycling system

Old carpet tiles used in offices have conventionally been disposed of mostly in landfills. To address this problem, in 2011 Suminoe Textile released ECOS®, eco-friendly carpet tiles series under the horizontal recycling system, which reduces waste and circulates resources at an unprecedented level. ECOS® has achieved a recycled material ratio of up to 84% by using SUMITRON®, continuous fiber made from recycled PET bottles, in the surface pile material, and by mixing recycled powder from used carpet tiles collected from the market with the backing material. ECOS® became the first product in the carpet industry to obtain Eco Mark certification under the new certification criteria. We are proud to say that ECOS® is Suminoe Textile’s proprietary product developed under the concept “Resources for the Future.”

Beginning of Heisei Period (1989) – Present (Brief Chronology of the Company’s History)

- 1998

- TRIPLE FRESH® deodorant treatment technology developed.

SUMINOE Co., Ltd. established. (2024 SUMINOE Co., Ltd. changed the trade name to SUMINOE Interior Products Co., Ltd.)

Kyoto Traditional Art and Craft Factory established, and traditional textile technology handed down from the Kyoto Factory.

- 1999

- Suminoe Logistics Co., Ltd. established.

- 2005

- Nara Factory, a carpet production factory, becomes independent and Suminoe Nara Co., Ltd. established.

Sumisho Airbag Systems Co., Ltd. jointly established.

- 2009

- A subsidiary, Suminoe Teijin Techno Co., Ltd., established jointly with Teijin Fibers Limited (now TEIJIN LIMITED).

- 2011

- Releases ECOS®, eco-friendly carpet tiles under the horizontal recycling system.

- 2013

- Suminoe Techno Co., Ltd. established, by consolidating Suminoe Koka Co., Ltd. and Suminoe Nara Co., Ltd.

Marks the 100th anniversary of the Company’s incorporation (130th anniversary of its founding).

- 2020

- Shares of CPO Co., Ltd. acquired, which becomes a subsidiary of Suminoe Textile Co., Ltd.

- 2022

- Shares of PRETERIOR-TEXTILE Inc. acquired, which becomes a subsidiary of Suminoe Textile Co., Ltd.

Shares of Seki Textile Co., Ltd. acquired, which becomes a subsidiary of Suminoe Textile Co., Ltd.

- 2024

- Our trade name was changed from Suminoe Textile Co., Ltd. to SUMINOE Co., Ltd.