As an industry pioneer, the SUMINOE GROUP has pushed forward with the development and application of advanced technologies that are friendly to human health and the environment. In 1998, the Group announced “KKR+A (Kenko [Health], Kankyo [Environment], Recycling and Amenity)” along with the Interior Environment Improvement Declaration. Since then, under its fundamental development philosophy “KKR+A,” the Group has been working on research and development of technologies and products that are friendly to people and the environment while promoting interior environment improvement and utilization of recycled materials. The Group also upholds the Fundamental Environmental Philosophy, to be followed in all aspects of our business operations. We have been positively tackling environmental preservation activities, including decreasing our impact on the environment, in accordance with the Activity Guidelines and activity goals. In April 2022, we announced the Second SUMINOE Environmental Declaration, which aims to ensure that our products will be used by many more people and to promote “KKR+A” around the world through implementation of global strategies. The entire SUMINOE GROUP will make concerted efforts to accomplish these objectives.

Fundamental Environmental Philosophy

Recently, deterioration of the global environment has rapidly been progressing. It is a mission in common among human beings who live on Earth to make efforts to preserve and improve the global environment and hand the beautiful earth down to our descendants. With this recognition, the SUMINOE GROUP will create a comfortable and rich society with the cooperation of all the employees positively tackling environmental preservation activities.

Second SUMINOE Environmental Declaration

-

- 1

- We shall provide healthy and environmentally friendly products.

We will provide safe and secure products to our customers by properly managing chemical substances used in our products based on the Green Procurement Guidelines regarding legal regulations and restrictions on materials used in products.

-

- 2

- We shall work to prevent global warming.

We will promote the effective use of resources by reducing losses of primary materials, auxiliary materials, water, and energy occurring in the production process. We will also update energy-saving facilities constantly, improve product quality, reduce the weight of products, simplify packaging and reduce its weight. At the same time, we will strive to increase the efficiency of transportation of materials and products, material utilization, and waste disposal during manufacturing, thereby promoting resource and energy conservation throughout the supply chain.

-

- 3

- We shall address the circulating society.

To contribute to the reduction of industrial waste and the recycling of resources in the life cycle of products, we will actively use recycled materials as part of our efforts to promote environmental conservation and the efficient use of resources.

-

- 4

- We shall promote the reduction of CO2 emissions.

To play a part in realizing a decarbonized society, we will develop and provide low-carbon products based on the Life Cycle Assessment (LCA) method. LCA is intended to comprehensively and quantitatively evaluate the impact of manufacturing activities on the environment while taking into consideration the entire life cycle of products ‒ materials, manufacturing, transportation, use, and disposal.

Activity Guidelines

In carrying out environmental conservation activities

-

- 1

-

We will positively promote energy-saving, resource-saving, and recycling with a consideration not to contaminate environment in all of our business activities.

-

- 2

-

We will try to preserve environment through products’ life cycle from production, sales to disposal by developing environment-friendly technology and products.

- Development of technology for energy-saving and resource-saving

- Development of recycling technology and recycling system

- Development of products and technology to replace materials which would put less load on environment and have more safety

- Development of product which could improve interior environment and contribute to health and comfort

-

- 3

-

We will try to live together with community through close communication and all employees will start action from whatever one can do.

-

- 4

-

We will try to maintain internal system to promote environmental protection and enhance environmental consciousness of all employees.

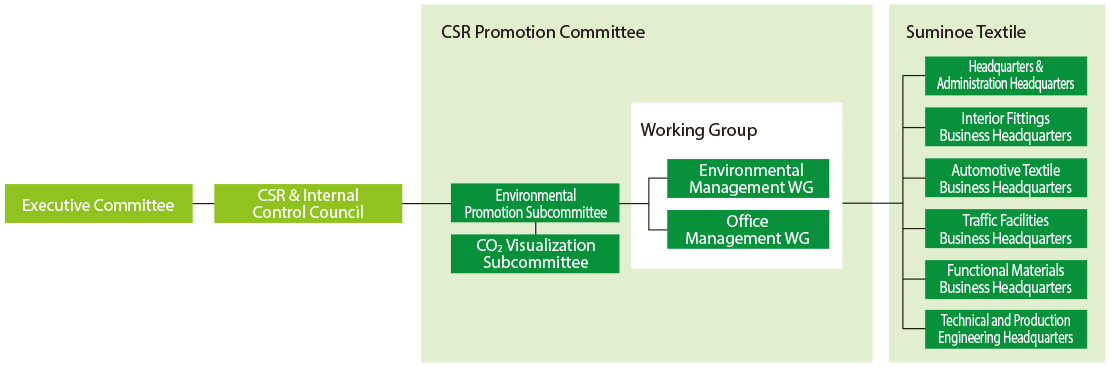

Environmental Protection Promotion System

The Environmental Promotion Subcommittee was set up within the CSR Promotion Committee. Environmental measures drawn up and finalized by the subcommittee are implemented in all divisions throughout the Group.

Introduction of Environmental Management System

The Nara Factory obtained ISO 14001 certification in fiscal 2001, making it the first among the Group to be awarded certification on environmental management. To date, five factories in Japan have obtained ISO 14001 certification, and one factory Eco Action 21 certification.

ISO14001:2015

Nara Factory, Shiga Factory-

- Screening and registration agency

- Japanese Standards Association

- Registration number

- JSAE 235

- Registration date

- May 2000

- Registration renewal

- 7th renewal completed (May 2021)

Teijin Tecloth Ltd.-

- Screening and registration agency

- Japan Quality Assurance Organization

- Registration number

- JQA-EM1519

- Registration date

- April 2001

- Registration renewal

- 7th renewal completed (April 2022)

- Owari Seisen Co., Ltd.: Head Office Factory, Ishikawa Factory

-

- Screening and registration agency

- Japan Quality Assurance Organization

- Registration number

- JQA-EM3114

- Registration date

- March 2003

- Registration renewal

- 7th renewal completed (July 2023)

Eco Action 21: 2017

- TANGO TEXTILE Co., Ltd.

-

- Screening and registration agency

- Institute for Promoting Sustainable Societies

- Registration number

- 0009522

- Registration date

- July 2013

- Registration renewal

- 5th renewal completed (July 2023)